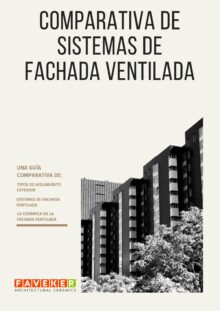

A ventilated facade is a construction solution that allows you to panel the outside of a building and leave an air chamber between the insulation layer and paneling. The main purpose of a ventilated facade is to physically separate the indoor environment from the outside of the building. This leads to more sustainable buildings. Energy No thermal No more Lower building The external bearing walls and insulation always remain dry and, therefore, fully preserve their function. The impact rain that could have been filtered through open joints will dry quickly due to the circulation of air in the ventilation space. Ventilated façades allow the correction of the thermal bridges producing an energetic saving when eliminating the contact between brackets and walls. This represents energy savings since both heat losses and gains are eliminated. The ventilated façade optimizes the temperature depending on the season of the year. The facades on modern homes are highly important when building from scratch or renovating an already-existing home. When it comes to single-family homes, choosing a ventilated facade brings two major benefits: Installing ceramic ventilated facades brings endless creativity and inspiration to architectural projects involving new construction work and even building renovations. The use of ceramic digital printing technology expands the esthetic possibilities with everything from pre-defined finishes to custom finishes, along with surface images and textures. A thermal building envelope – more commonly known as a ventilated façade – is an outer skin around a building that totally eliminates the thermal bridges responsible for 30% of energy losses from buildings. It creates a safe, efficient, sustainable barrier between the outside environment and inner atmosphere of the building. A ventilated façade is an unbeatable solution since it decarbonises buildings, minimizing their energy requirements and hence their energy consumption. FAVEKER® also uses fully recyclable materials with a high recycled content, leading to the creation of building envelopes that combine efficiency with sustainability. Thanks to this kind of façade system, buildings go one step further than merely complying with requirements in the fields of energy, safety and sustainability by improving on these stipulated limits, with the achievement of NZEB (nearly zero energy buildings) or even PEB (positive energy buildings). The ventilated façade guarantees an improvement of the thermal insulation of the building, since it allows to install continuous insulators between the external support of the supporting wall and the exterior cladding of the façade. The cladding of the ventilated façade protects the supporting structure, the thermal insulation and the substructure of the climatic influences, because it is resistant to rain. • In summer, the sun shines directly on the cladding and not on the building In winter other factors come into play, since solar radiation is not enough to achieve these air movements. Fire safety is another key aspect of ceramic ventilated facades. FAVEKER®’s extruded ceramic panels are classified as non-combustible by UKAS-ISO 17065 in reaction to fire, meaning they do not contribute to the spread of fire. In addition to the fire resistance provided by extruded ceramics, sectorization barriers are added. These are constructive elements that deploy in case of a fire to prevent its spread throughout the building. Sectorization barriers are firebreak obstacles located within the ventilated chamber of the facade. Their purpose is to prevent the fire from spreading throughout the building in case of an outbreak. These fire barriers close the interior chamber and prevent the fire from penetrating the entire ventilated chamber. The safety of this solution is backed by the UKAS-ISO 17065 fire propagation certification, ensuring compliance with regulations. The phases may vary depending on the type of project, whether new construction or renovation, the type of ceramic panel chosen and the orientation. However, the process essentially involves: • Laying out the brackets and profiles: measuring and marking to install the profiles. • Assembling the profiles: arrangement, levelling and anchoring with brackets. The installation of a ventilated facade is simple yet requires the installer have a certain degree of technical knowledge. At Faveker we have installation manuals and technical data sheets for our products to make assembly even easier. With the technology and engineering used to design and manufacture our systems, top-quality products with distinctive features are ensured: Optimum anchorage, with spans of 1200 mm. and 1500 mm. between supports (depending on the thickness). Savings on materials and labour, thanks to the slabs’ high mechanical resistance. Smart Clip, guaranteeing swifter assembly work, particularly with formats like 600×1200 mm. Precise optimum modulation, using our standard formats. The possibility of modulation on a vertical or horizontal plane or even with a combination of both. The 500×1500 mm. format opens up broader creative potential. Optimized volumetric effects, a select looking design, thanks to the raised reliefs on the ceramic slabs. XL, 600×1800 mm. hollow core panels that unite high performance with resistance and design appeal. Plus, at Faveker, we have a technical office with engineers and advanced building specialists to collaborate on your projects. From initial guidance with the selection of materials, solutions and types of thermal envelopes, to certification of correct installation. FAVEKER FAÇADE

The FAVEKER® ceramic ventilated façade thermal envelope systems provide savings, energy efficiency, sustaintability, comfort, habitability, aesthetic, resistance and durability to the projects.

What is a ventilated façade?

Why is a ventilated facade more sustainable?

savings

bridges

condensation

maintenance costso How is condensation eliminated in buildings with ventilated envelopes?

How are thermal bridges corrected with ventilated solutions?

The advantages of FAVEKER® ceramic skin

Why choose a ventilated facade

for a single-family home? Innovative buildings and

designer architecture Long-lasting and sustainable

ceramic envelopes.

How can you improve the thermal insulation of a building with a ventilated facade?

How does the ventilated façade

work in summer?

How does the ventilated façade

work in winter?

• Heats the air in the chamber, decreases its density and convection rises, with fresh air taking its place.

• This is the phenomenon called “the chimney”, which prevents the accumulation of calories in the façade.

• The thermal insulation provides additional protection against atmospheric agents.

• More comfortable and habitable homes.

• In winter the façade acts as a heat accumulator, helping the air chamber to the thermal stability of the system.

• The thermal insulator provides a maximum thermal accumulation of the interior components that prevents the loss of heat inside the building. Ceramic Ventilated Facade: High Fire Safety

What are Sectorization Barriers?

How do you install a ventilated facade?

• Fixing the brackets: drilling into the support wall to insert and install the fixing elements, the Thermostop insulation and other necessary anchoring accessories.

• Placing the insulation over the support wall.

• Inserting EDPM joints made of ethylene propylene diene rubber.

• Inserting the cramp iron into the profiles and installing the ceramic pieces.

The keys to ventilated facade technology

Comprehensive Faveker® advising

on ventilated facades

1 Durability and resistance, with no change in their properties. Made of long-lasting materials that are unaffected by climatic conditions (damp, wind, solar radiation etc.).

2 Increased insulation, and better protected insulating materials. Specific types of insulation can be used, protected by the outer ceramic skin.

3 Design appeal, from basic finishes to customized ones.

4 Lightweight and easy to clean, with zero maintenance. Lower in weight and higher in resistance.

5 Efficient and sustainable. The façade systems guarantee energy savings while also caring for the environment, thanks to their composition and manufacturing process, with Zero Waste.

1 Household savings, as it optimizes the energy bill.

2 More comfortable and habitable homes.