The importance of prevention in fire safety

Factors influencing fire spread and the challenge of technological advances in view of safety regulations

We know that technology advances faster than regulations, and regulations require more time to meet MINIMUM requirements. Nothing prevents us from complying with regulations when aiming for the utmost safety. Unfortunately, the only deterrent to the latter is usually the amount of financial resources.

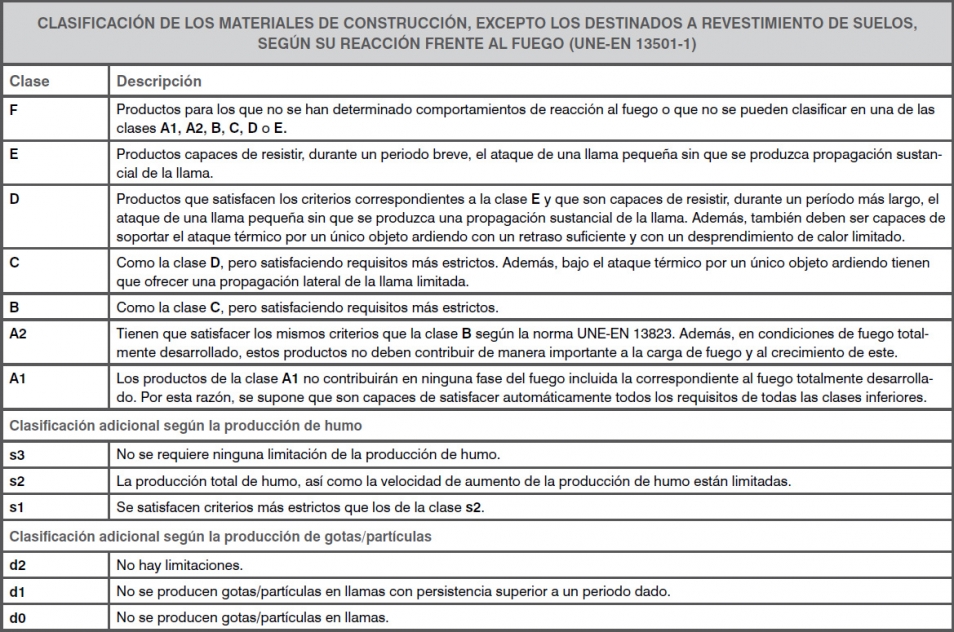

There is plenty of national and international technical literature describing how materials behave towards fire. Materials can be non-combustible (ceramic, stone…), combustible (wood…) or flammable (gasoline…). Based on this, they are classified according to their use in the construction sector:

Nothing prevents us from always using A1 systems for facades, thus reducing risks, and above all, avoiding flammable materials (even when part of a composite system). For example, a flammable material between sheets of a non-combustible material which melts at temperatures lower than those that can occur in a fire flame (depending on many factors, but usually ranging between 900°C and 1,300°C), will eventually expose the flammable material when exposed directly to flames.

Advantages and characteristics of ventilated facades

It is worth noting that ventilated facades are the most recent type of facade. Seeking efficiency, comfort and operability, they have been a technological evolution in building envelopes for 35-40 years now. As concerns recent building facades, this type is the most innovative. There are many benefits to ventilated facades as they combine acoustic (noise) insulation, heat and temperature insulation (high or low), wind protection, increased interior comfort, and work alone, requiring no external energy input as they rely on the energy present in the atmosphere. Ceramic ventilated facades are a type of lightweight facade available for a medium-range cost, which makes for immense creative possibilities for architecture professionals, especially considering they can be comprised of highly sustainable materials if selected correctly

Strategies for improving fire safety

As an extremely safe system, not only do they not contribute to any fire that may break out, but they also help extinguish fires by sectorizing and preventing any spreading. How? By using all measures available to us: not only by using non-flammable materials but also by being much more selective in the use of non-combustible materials, such as the ceramic found in FAVEKER ventilated facades. We have a great ally that has been historically used in architecture and is capable of creating safe systems: ceramic. There are even products made of ceramic baked at high temperatures that are even more suitable for resisting fire conditions. Sectorization barriers should be used as they take advantage of the convective chamber benefits of ventilated facades when deployed during a fire. The combination of the latter with ceramic skins baked at high temperatures is a very safe option since the barrier seals against a non-combustible skin, which also does not crack or burst, thus protecting the chamber and the structural elements, as well as the load-bearing wall.

Evaluation of fire spread and reaction

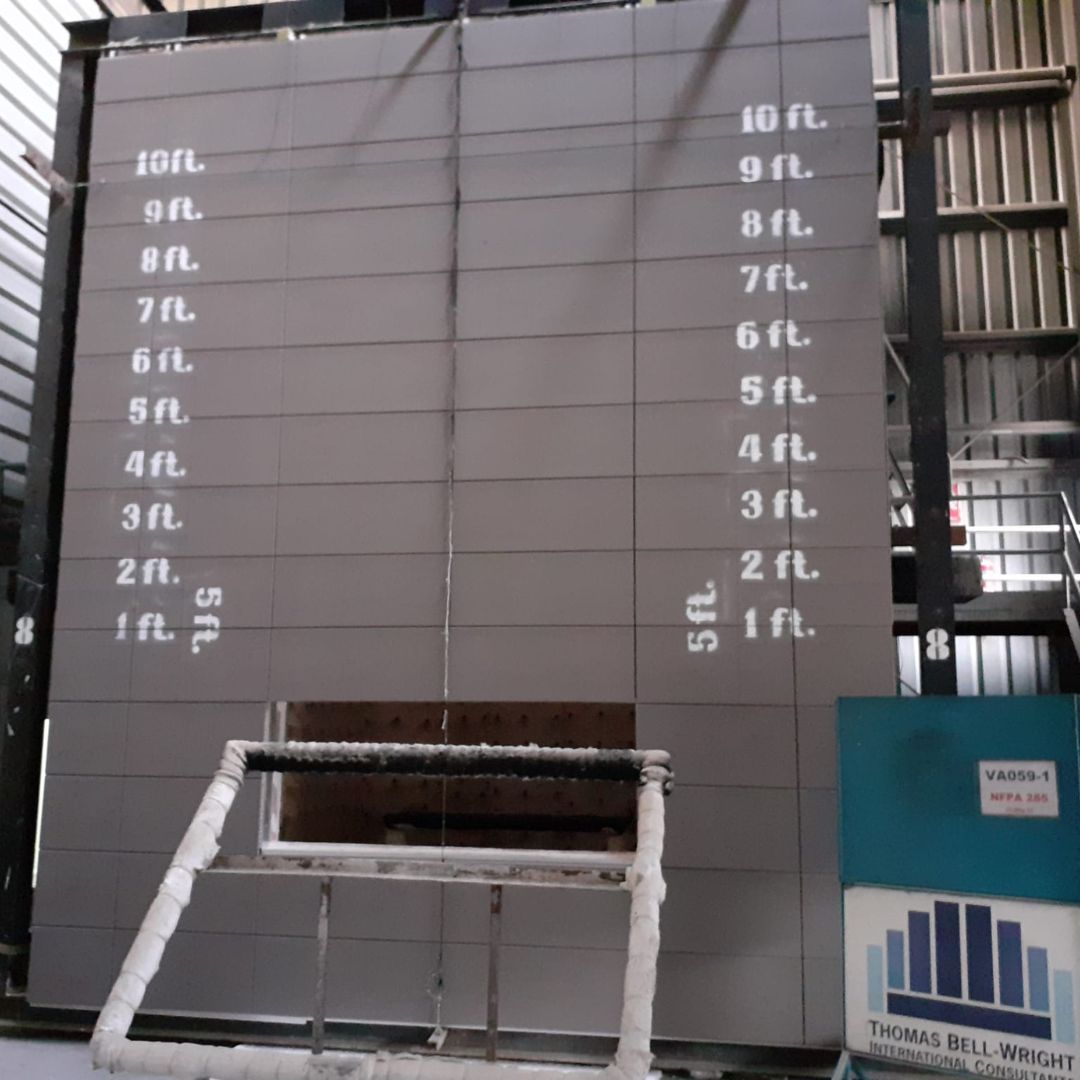

To this end, it is worth remembering that there is a test against fire spread in a chamber (NFPA 285-2019) available, which assesses the complete system with each and every one of the corresponding elements, on a real scale and with real fire. It starts inside a room with direct external fire added to the facade simultaneously after the first 15 minutes of interior fire, for a total duration of approximately 1 hour. The fire burns for the initial 45 minutes and the subsequent 15 minutes are for observation after turning off the burners to evaluate self-ignition.

Therefore, there is currently a European standard, UNE-EN 13501-1:2018, based on fire reaction, which classifies construction materials and elements in accordance with their behavior in the face of fire. The best classification within this standard is class A1-A2, which indicates that the material is non-combustible and does not contribute to the spread of the fire. This is the result that FAVEKER has obtained in all testing. It is important to note that the term “fireproof material” does not mean that the product will not burn under any circumstances, but rather that it has the ability to not burn, not spread the flame and extinguish the fire automatically when the ignition source is removed.

Conclusions and recommendations for safe building design

In conclusion, we must understand prevention as a maxim under which we design buildings assuming that a major fire could occur, and not seeing it as a remote possibility. The same is true in the automotive sector, where it is assumed that all vehicles can be involved in an accident.