Ventilated facade anchors and fastenings: the invisible parts of assembly

When you look at a ventilated facade on a building, many parts are invisible to the eyes. Each one of them is essential yet some remain hidden after assembling the envelope. Find out about all the parts of a ventilated facade and what types of anchors there are to install and secure one.

What are the parts of a ventilated facade?

A ventilated facade is comprised of mainly four parts which, from the outside in would be: the outer leaf, the fixing system, the air chamber and the thermal insulation on the outside of the building wall.

1. The visible building envelope

FAVEKER® supplies highly resistant alveolar extruded porcelain ceramic for the outer leaf, or the visible building envelope, for extra sustainability as it’s 100% recyclable with a composition of more than 52% recycled materials. The esthetic possibilities are endless thanks to digital printing technology, which makes it possible to reproduce any design on ceramic.

2. The fixing system on a ventilated facade

The next part is the fixing system. It’s comprised of brackets that support and secure the profiles where the ceramic panels are positioned. These systems can be combined with different types of materials. In our case, the brackets and profiles are made of aluminum alloy, stainless steel clips, nuts and bolts, EPDM or ethylene propylene diene seals and polypropylene Thermostop insulation.

3. The air chamber

The ventilated facade system leaves a space between the insulating layer and the cladding. This chamber allows air circulation through a convection effect to achieve sustainable, efficient and comfortable buildings with the thermal inertia from the ceramic ventilated facade system.

4. The outer facade insulation

The fourth part of any ventilated facade is the outer insulation, which is usually made of rockwool or fiberglass. The biggest advantage of insulating the facade from the outside of the wall is that it helps eliminate thermal bridges and, therefore, increases the energy savings in the building.

Is there a single fixing system for all ventilated facades?

There is no single system for fixing all ventilated facades, as each project has its own unique characteristics. Aspects like requiring a certain fire resistance or wind resistance, the conditions of the support surface, the location, the orientation of the panels, the heights between the forged steel, the alignment of the joints or the format mean there is an ideal fixing system for each solution so that each ventilated facade is successfully installed with guaranteed durability. Irrespective of the system, there is one essential factor: the solution chosen must be officially approved.

Why must the fixing systems on facades be officially approved?

Fixing systems must be tested along with the cladding by an external laboratory and must meet a series of conditions the future ventilated facade will be subjected to, such as resistance to wind, fire, impacts and frost-defrosting in addition to extreme temperatures, not to mention protection from rain and drainage capacity.

The results are detailed in a document known as the European Technical Assessment (ETA) which is available to the public for anyone who wishes to view it and is going to use the ventilated facade for their project.

FAVEKER® recently updated its ETA through the Catalonia Institute of Construction Technology (ITeC), including new systems and XXL formats (up to 1.8 meters long). This assessment refers to the FAVEKER® kit for external cladding on ventilated facades.

Which systems for ventilated facades are used by FAVEKER®?

The systems officially approved to secure ventilated facades can be divided into two groups:

- Those that secure panels using clips or iron cramps.

- Those that hold the ceramic panels in place with horizontal profiles.

Both are hidden anchoring systems; in other words, they’re not visible once the ventilated facade is installed which makes for a nicer look and overall final building design. One of the main advantages of all FAVEKER® fixing systems for ventilated facades is that ceramic panels up to 1500 mm long can be positioned without needing to use intermediate support profiles, which saves material and the time it takes for installation. Plus, extrusion manufacturing prevents having to apply any type of machining to the ceramic panels after firing, which would otherwise significantly weaken the panels.

Hidden anchoring systems for facades using clips or iron cramps

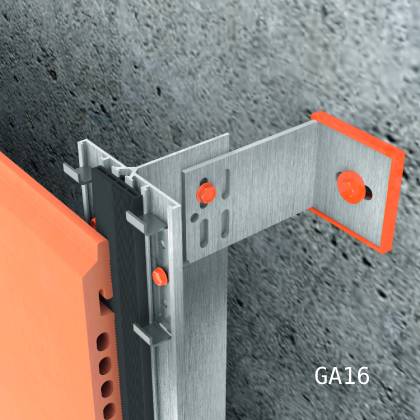

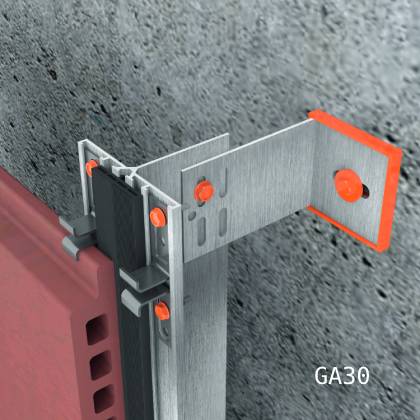

The group of hidden anchoring systems using clips or iron cramps includes the FTS 502B, with all of its variants based on the ceramic panel being used: GA16, GA20 or GA30. In all cases, the system is identical as far as its composition: brackets and grooved profiles joined together with nuts and bolts, an EPDM seal and Thermostop insulation. The grooves on the profiles facilitate installation and alignment of the clips. The only thing that differs between the variants of the FTS 502B system is the type of clip used for each ceramic panel model. The fire reaction of all of them is Class B-s1, d0.

A raised access system with FTS 502B anchors for GA16 ceramic panels

The FTS 502B for GA16 is used with a double clip that secures each panel and the upper layer, which provides additional fastening in the event of breakage. Plus, this clip is unique in that it makes for a raised access system. In other words, once the facade is installed, any of the ceramic panels can be removed and replaced without needing to dismantle any other installed part. This is quite useful when any damaged parts need to be replaced or work needs to be done on the ventilated chamber after installation.

Clip anchoring for GA20 ceramic panels: simple installation

The FTS 502B for GA20 uses a simple type of clip that can support the weight of the ceramic panel when placed on the bottom layer, and secure it from movement when placed on the upper layer. This system is particularly easy to install as the clip simply needs to be screwed in, and it’s a system that allows a ceramic panel position with a vertical orientation to take advantage of the alveolar structure of the GA20 extruded ceramic panel by FAVEKER®. There is also a variation, the 502B+, which uses a clip that’s 1 mm thicker to be able to increase the bearing resistance when using large-format panels and when required by the project conditions. A vertical fixing system can also be used.

The clip fixing system for thicker panels

The FTS 502B system for GA30 is quite similar to the one used with GA20, but it uses a 19 mm clip to better support panels that are heavier due to the considerable thickness at 30 mm.

Hidden anchoring systems for facades using profiles

The second group of systems includes those fixed with continuous horizontal profiles and non-continuous profiles to secure the cladding:

- FTS 502A

- FTS 506

- FTS 506 GR

- FTS 505

These systems do not include EPDM seals and the fire reaction is Class A1. They are comprised of standard vertical profiles with other horizontal profiles positioned over them to make them continuous. The main advantage of this kind of systems is that they adapt quite well to facades designed with staggered joints, which allows for innovative facade esthetics in addition to considerably increasing the wind resistance.

Hidden anchoring with continuous horizontal profiles for ventilated facades

The FTS 502A system is used for GA16 ceramic panels by FAVEKER®. This system is comprised of a C-shaped aluminum continuous horizontal profile that fits into the grooves on the back of the ceramic panels. It’s a system that also offers raised access meaning panels can be easily removed and replaced.

Fixing systems with continuous horizontal profiles for GA20 panels

The FTS 506 system is the continuous horizontal profiling version for the GA20 and there is also a variation, the FTS 506 GR, which uses non-continuous sections with 15 cm profiles to save material as well as the time it takes for installation in addition to increasing the wind load over the FTS 520 B system.

Vertical assembly with the FTS 505 system

FTS 505 is an advanced ventilated facade fixing system that allows vertical assembly of GA16, GA20 and GA30 ceramic pieces. This type of anchoring with an EPDM profile provides protection against the entrance of water, is suitable for staggered joints and ideal for projects aiming for design verticality.

Find all the fixing systems you need for ventilated facades at FAVEKER®

The range of fixing systems for FAVEKER® ventilated facades is quite large. The use of a system officially approved by an independent external authority is essential to achieving results that guarantee safety, durability and optimal performance. Download our installation manuals and try out our new 3D viewer to see the different fixing systems before and after installing a ventilated facade. Contact our experts for personalized advice on your ventilated facade installation project.